It’s safe to say that most European stage machinery manufacturers and owners have heard about a document called a “Declaration of Conformity”. However, we could probably say that not too many are aware that a document called a “Declaration of Incorporation” also exists.

For the purpose of this article, let’s call the Declaration of Conformity a “DoC” and the Declaration of Incorporation a “DoI”. A DoC is what the legislator calls as “a passport facilitating the free movement of machinery in the single market”. In plain English, it means that a DoC is a document compiled and signed by the machinery manufacturer, which states that a specific machinery is in full compliance with the Essential Health and Safety Requirements [EHSR] as described in Machinery Directive Annex I.

A DoI is a document that needs to be produced by a manufacturer, when a Partly Completed Machinery [PCM] is placed onto the market (made available for sale) or put into service (installed). The scope of the DoI is to inform the manufacturer of the final machinery which of the applicable EHSRs of Annex I for the machinery have been applied and fulfilled. And it must also indicate that the PCM must not be put into service until the final machinery the PCM will be incorporated into has been declared in conformity with the relevant provisions of the Machinery Directive. So, the DoC is associated with a (completed) machinery and indirectly says: “Homework done, you are safe to use me”, while the DoI that is associated with the partly completed machinery says “missing relevant parts, so please… don’t use me yet”.

Completed and Partly Completed Machinery

If a machinery is an assembly, fitted or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components, at least one of which moves, and which are joined together for a specific application 1, a partly completed machinery is “almost” that. In fact, the definition of partly completed machinery means an assembly which is almost machinery but which cannot in itself perform a specific application. A drive system is partly completed machinery. Partly completed machinery is only intended to be incorporated into or assembled with other machinery or other partly completed machinery or equipment, thereby forming machinery to which this Directive applies 2.

Therefore, it is clear that a PCM is not a completed machinery. Yet, when can a manufacturer declare that a machinery is not complete and how do they inform the market (the owner, the integrator, the final machinery manufacturer) of what has been left incomplete?

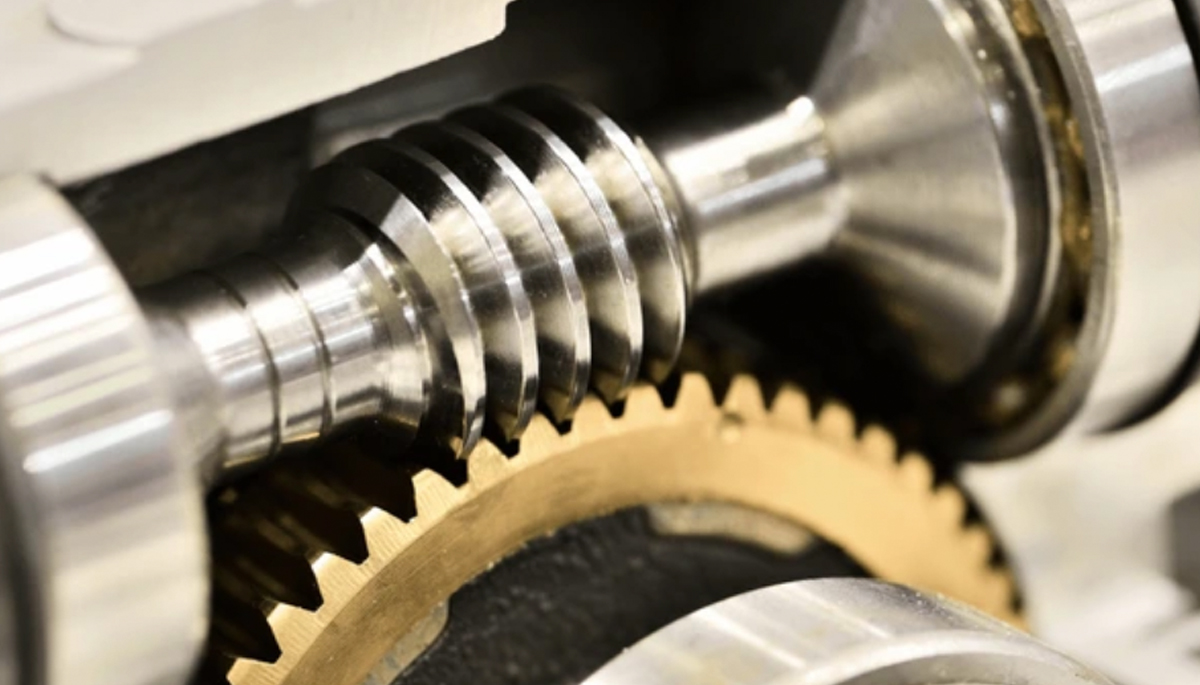

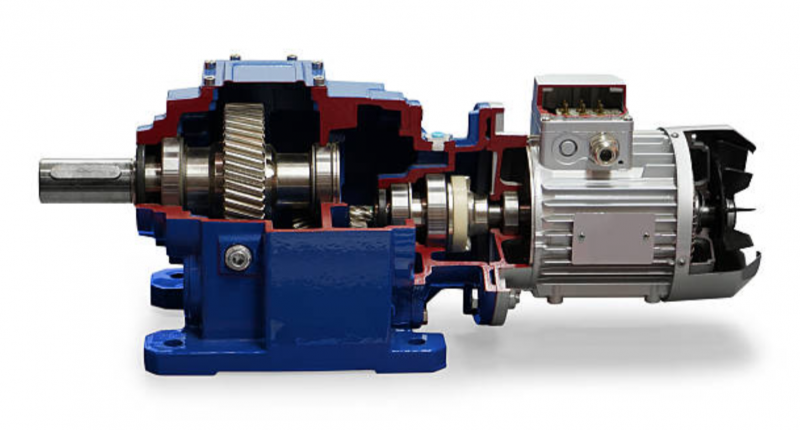

Here is a classic example of a PCM:

Machinery manufacturers may outsource the design and manufacturing of a winch lifting mechanism to a third-party company, and then they “complete” the PCM with the missing parts (load-bearing lines, accessories, guards, electrical equipment, safety-related components, control system, user interface, etc.). As a result, the drive system3 which is made up of a gearbox, a motor, output shafts and a drum, assembled into a load-bearing frame, representing the lifting mechanism of a stage winch (for example) is generally considered a PCM.

Even so, why is a drive system like the one described above, according to MD 2006/42/EC, generally NOT considered as completed machinery? This is due to the fact that without the missing parts, the assembly cannot perform a specific application, and this condition is irrespective from its conformity with the Machinery Directive requirements (because there are compliant… and not compliant PCMs).

Figure 1 – A Motor and Gearbox.

Specific Application

Each stage machinery should be designed according to its established intended use. The designer should identify the machinery limits, determine the permissible use and draft a risk assessment based on these initial conditions. Hence, it is the intended use that guides the hazard allocation, the correct risk reduction and ultimately the intrinsic safety of the machinery. If an electric chain hoist is designed to be integrated with other electric chain hoists with the intended use of lifting shared loads, it needs to be able to perform the specific application of lifting shared loads in order for the assembly of machinery to be considered a completed machinery.

Some chain hoist manufacturers may consider a PCM as a hoist with the intended use of being integrated with other chain hoists, but placed on the market without electrical equipment. They believe that the specific application of lifting shared loads cannot be achieved unless the chain hoists – PCMs – are integrated within the machinery installation and completed with the missing parts (accessories, electrical equipment, control system, user interface, etc.). Other manufacturers may choose to claim full compliance to the Machinery Directive, and consequently declare that the chain hoists with the intended use of lifting shared loads are fully machinery capable of performing a specific application, based on the interpretation of MD 2006/42/EC, Article 2, point (a), indent 1 sentence “fitted or intended to be fitted with a drive system”.

The intention for the machinery of being fitted with a drive system and related electrical equipment is considered in the machinery risk assessment. The machinery is designed in such manner to reduce, as much as possible, the risks related from the incorrect integration of the drive system with the safety-integration requirements being fully explained and specified within the user manual.

Declaration of Incorporation

It is understood that a PCM cannot fully comply with the essential health and safety requirements set out in Annex I, since some of the risks may be the result from the simple fact that the machinery is not complete or because some of the risk reduction measures are subordinate to the reliability of the integrated control system. However, as previously stated, the manufacturer of the PCM needs to disclose which of the applicable EHSRs of Annex 1 have been applied and fulfilled to the final machinery.

How is this done? It’s simple: the EHSRs that have been fulfilled need to be mentioned in the DoI and the ones that have not been fulfilled should not be mentioned. For example, if we read in a DoI that point 1.1.5 has been fulfilled but the document does not mention that point 1.3.9 has been addressed; this means that the machinery has been designed in such a way to facilitate its handling but doesn’t have any protection against uncontrolled movement. So, the chapters that we normally see in a Declaration or Incorporation are the chapters of Annex I of the Machinery Directive in which specific EHSRs are described.

How Important is the Correct Interpretation?

Once explained, the concept of partly completed machinery applied to stage machineries makes sense and it is applicable to many “almost” machinery. However, there is a delicate factor to bear in mind, which is that the directive warns you from claiming false exclusions.

The legislator states that machinery that fulfils the definition of the three indents of Machinery Directive Article 2 (a)4; which means that they can operate independently by performing a specific application, but only lack the necessary protective means or safety components, such as guards, but will not be considered to be partly completed machinery. Again, the Machinery Directive explains very clearly that such incomplete machinery does not meet the requirements of the MD and must not be CE marked and cannot be placed on the market or put into service.

What do they really mean and what does this warning have to do with stage machinery? In order to be compliant, partly completed machinery needs to tick three boxes:

a) It needs to be almost a machinery, in the sense that it is “not a completed assembly” of linked parts with at least one of which moves.

b) It cannot perform a specific application.

c) It is intended to form a machinery within the scope of Machinery Directive.

Therefore, if we have a drive system made of a gearbox, a motor, output shafts and a drum, assembled into a load-bearing frame with a connection strip, a power cable (but not a plug), a remote pendant with a GO button (but not an E-STOP), that has a disassembled wire rope (but not the attachment point). You cannot really claim that this is partly completed machinery just because it is not completed. In essence, this would be a non-compliant full machinery capable of performing a specific application without having fulfilled the MD EHSRs.

Sometimes, completed machinery that is missing some parts can be confused with PCMs.

If a part that’s missing is not a constitutional part of the machinery – such as a the motor, the load-bearing lines, the electrical equipment – and does not give rise to the substantial impact on the safety of the machinery and the manufacturer provides clear information concerning the installation of the missing parts so that the safety and compliance of the final machinery is guaranteed, then the completion of the machinery can be done according to those instructions, prior to putting it into service and the machinery can be supplied with a Declaration of Conformity.

Interpretation is all that matters…

In the future, we will talk about the assembly of machinery comprising new and existing equipment, replacements and revisions, second-hand machinery and control system integrations.

1. MD 2006/42/EC, Article 2, point (a), indent 1.↩

2. MD 2006/42/EC, Article 2, point (g).↩

3. A drive system should not be confused with a variable speed drive [VSD], a frequency inverter or a controller which are part of the machinery electrical equipment, but as stand-alone items that are not considered a machinery or a partly completed machinery.

The legislator in fact refers to “an assembly which is almost a machinery” meaning a product that is similar to machinery in the strict sense of Article 1 (1) (a), and that is to say an assembly consisting of linked parts or components; at least one of which moves but which lacks some elements necessary to perform its specific application.↩

4. Which means they are an assembly, fitted or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components, at least one of which moves, and which are joined together for a specific application, etc.↩