Impact assessment study of the Machinery Directive WG1 meeting

The European Commission is seriously considering the revision of machinery directive; in 2019 the EC carried out interviews and a public survey in order to collect feedback from the industry stakeholders.

The consultation was made by 98 semi-structured interviews and 528 submission of open public consultations.

On the 19 February 2020, the European Commission – Engineering, Maritime and rail industries – organised a meeting to discuss the output of such survey and the proposed amendments addition to the MD 2006/42/EC.

The following topics were discussed:

— Clarify the scope, including the exclusions, borderline with other legislations and definitions

— Align it to the New Legislative Framework

— Allow innovative technologies for certain applications

— Cover new potential risks related to AI, IoT, ML and Cybersecurity2

On the 20 May 2020, CCMC3 issued the official report of the meeting held in February.

The overall impressing emerged from the report, is that the large industry is of the opinion that potential new risks are already covered by the requirements of the existing MD and no changes are necessary in relation to new technologies.

However, some member states request changes in relation to Software and Software updates, emergency stop, scope and definitions, digital format for documentation and — due to emerging trend and related problems and needs – collaborative robots, IoT and AI applications. ANEC4 also pointed out the need of changes in relation to new technologies (Cybersecurity and ML)

The report was very long, dense of information and proposals still under discussion, however Blumano extract a few topics that may be of public interest for the event industry.

In this article we report some of the points under discussion within the MD Working Group.

Highlights

Addressing new challenges posed by technological developments in digitalisation

(Proposed changes)

Software and software updates.

— Two categories of updates were considered: minor updates for patches and increased functionality and security, and major updates that change the intended use of the machinery.

— Minor updates are considered to fall under maintenance.

— Major updates that change the intended use of the machinery or performance levels can be considered to be covered by substantial modification.

— Software which ensures a safety function and is placed independently on the market should explicitly be covered by the MD and be considered a safety component.

(Proposed changes)

Annex I – 1.2.1 Safety and reliability of control system.

The safety functions cannot change outside the limits of the manufacturer’s defined scope.

This scope is validated and guaranteed by the machine manufacturer, regardless of any modifications to the settings or rules generated either by artificial intelligence or by operators in charge of the learning phases.

(Proposed changes)

Annex I – 1.2.3. Starting

For machinery functioning in automatic mode, the starting of the machinery, restarting after a stoppage, or a change in operating conditions may be possible without intervention, provided this does not lead to a hazardous situation.

(Proposed changes)

Annex I – 1.2.4.3. Emergency stop

Machinery must be fitted with one or more emergency stop devices to enable actual or impending danger to be averted.

The following exceptions apply:

— machinery in which an emergency stop device would not lessen the risk, either because it would not reduce the stopping time or because it would not enable the special measures required to deal with the risk to be taken,

— portable hand-held and/or hand-guided machinery.

Changing the scope and definitions

— Provide clarification between assembly, integration and group of machines.

— Provide criteria for substantial modification.

— Removing the exclusion of Art.1.2(b) on fairground equipment.

— Introducing the role of an installer supported only for limited cases (e.g. installations of platform lifts)

(Proposed changes)

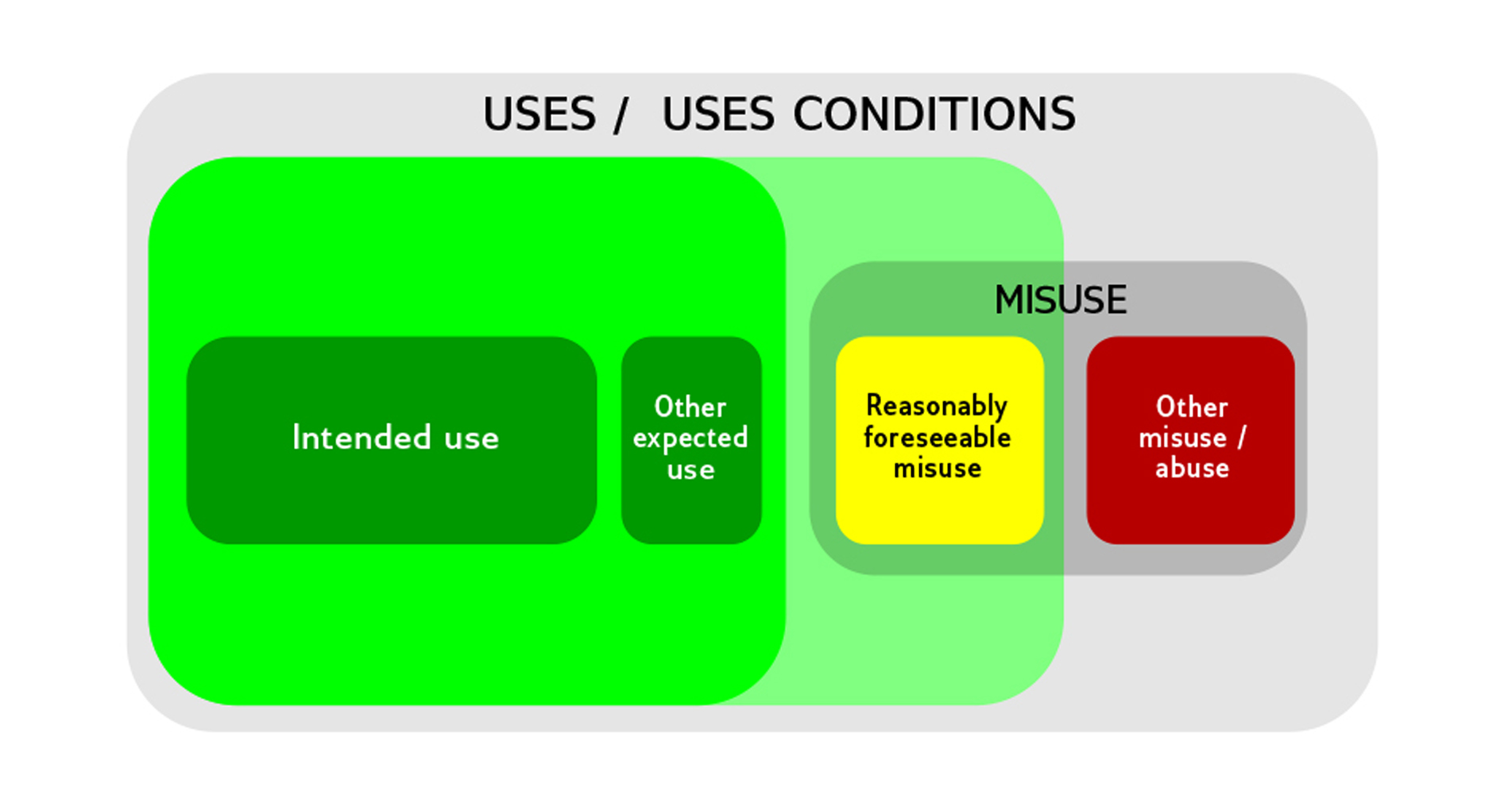

Article 2 Definitions – Machinery

an assembly, fitted with or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components, at least one of which moves, and which are joined together for a specific application and for a use as defined by the manufacturer. The energy stored in the equipment must be greater than the energy generated by a single human or animal action for it to be considered machinery.

(Proposed changes)

Article 2 Definitions – PCM

an assembly which is almost machinery but which cannot in itself perform a specific application. Any device installed after the machinery on which it is assembled has been put into service is not deemed partly completed machinery.

(Proposed changes)

Annex II Declarations – PCM

Annex II B. DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

This declaration and translations thereof must be drawn up under the same conditions as the instructions (see Annex 1, section 1.7.4.1(a) and (b)), and must be typewritten or else handwritten in capital letters.

The declaration of incorporation must contain the following particulars:

4. a sentence declaring which essential requirements of this Directive are applied and fulfilled and that the relevant technical documentation is compiled in accordance with part B of Annex VII, and, where appropriate, a sentence declaring the conformity of the partly completed machinery with other relevant Directives. These references must be those of the texts published in the Official Journal of the European Union. Partly completed machinery cannot claim to meet the requirements of this Directive without satisfying any essential requirements;

(Proposed changes)

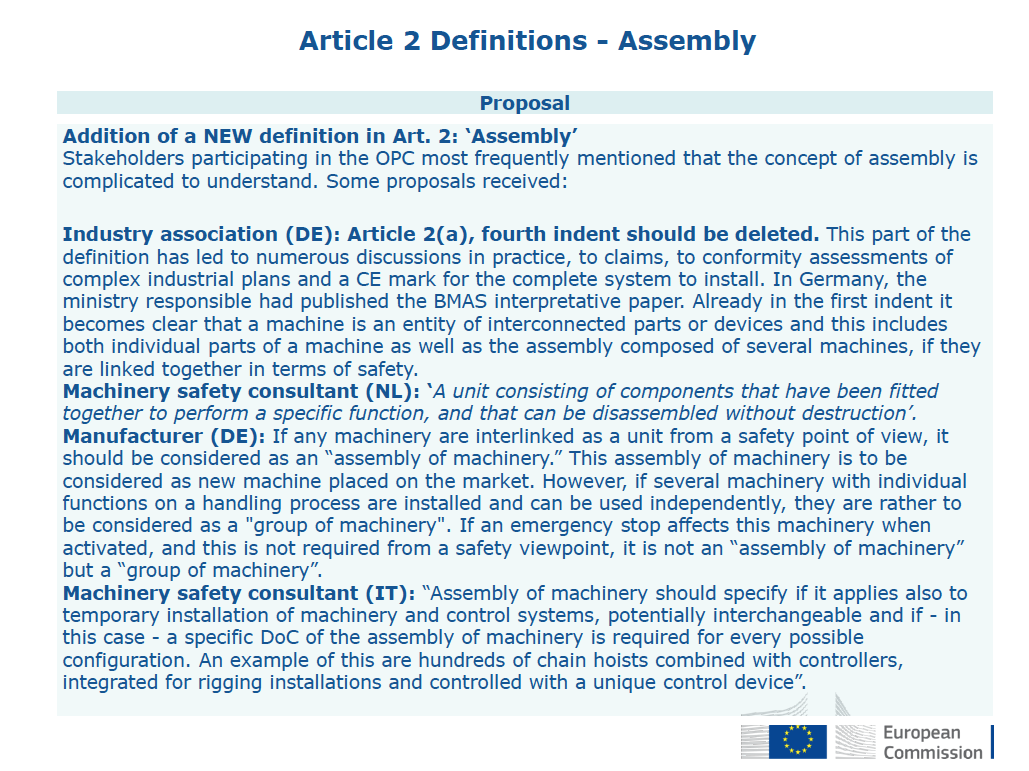

Article 2 Definitions – Assembly

“Assembly of machinery should specify if it applies also to temporary installation of machinery and control systems, potentially interchangeable and if – in this case – a specific DoC of the assembly of machinery is required for every possible configuration. An example of this are hundreds of chain hoists combined with controllers, integrated for rigging installations and controlled with a unique control device”.5

(Proposed changes)

Article 2 Definitions – Safety function

Safety function’ means a function which has an active effect on the risk, such that its failure may immediately result in a heightened risk. A simple warning system does not perform a safety function under this definition;

Adapting the EHSR on requirements for completely enclosed carrier or control for movements for slow speed lifts – OPC results on completely enclosed carriers in slow-speed lifts

(Proposed changes)

— Lifts intended for persons and goods are not as well protected against the risk of falling with alternative solutions than a fully enclosed carrier.

— Allowing alternative technologies yielding the same or higher level of safety than completely enclosed carrier might be a solution for other types of lifts.

Allowing digital formats for documentation – Delivery of user manual

(Proposed changes)

— To minimise the risks of digital tools, the options for a printed QSG and access to the full documentation in printed form upon requests should be considered.

— In the case of allowing digital documentation, an adaptation of the EHSR together with the Guide would ensure better clarity of the requirements.

Annex IV (part 3)

(Proposed changes)

Proposal to add the following type of machinery under the scope of Annex IV

— Machinery used to perform operations under a load or a vehicle.

What’s next?

Blumano will continue monitoring the development of the Machinery Directive 2006/42/EC revision in conjunction with the work in place to harmonise the EN 17206 to such directive.

References

1. The Machinery Working group is the EC expert’s group for the Machinery Directive 2006/42/EC.

2. AI = Artificial Intelligence;

IoT = Internet of Things, which is the use of smart sensors and actuators to enhance manufacturing and industrial processes. Also known as the industrial internet or Industry 4.0, IoT leverages the power of smart machines and real-time analytics to take advantage of the data that machines have produced in industrial settings for years;

ML = Machine Learning, which is a method whereby the target or goal is defined and the steps to reach the goal is learned by the machine itself through training. Instead of a programmer writing the commands to reach the target, the programme generates its own algorithms based on example data and a desired output.

3. The CEN-CENELEC Management Centre (CCMC), located in Brussels, is in charge of the daily operations, coordination and promotion of all CEN and CENELEC activities. CCMC is responsible for handling the tasks assigned to it by both CEN and CENELEC General Assemblies, the Administrative Boards and the Technical Boards. CCMC is also responsible for correspondence and liaison with the services of the European Commission and the EFTA Secretariat.

4. ANEC is the consumer voice in standardisation.

5. Note: BLUMANO is one of the 528 stakeholders who participate to the public consultation. We raised the issue of the Declaration of Conformity for assembly of machinery related to rigging chain hoist.