The dynamic world of stage production relies heavily on complex machinery to bring artistic visions to life. From lifting scenery to moving platforms, the precise and safe operation of the stage equipment is essential. A key component in ensuring this safety is the appropriate use of control devices, and among these, the deadman handle plays a critical role. This article will explore the fundamental principle that when an operator is required to control stage machinery, that operator must have the means to prevent the machinery from moving on demand. We will delve into why deadman handles are essential in certain scenarios and how they differ from other safety mechanisms like emergency stops.

The Necessity of Operator Control and Prevention of Unwanted Movement

At the heart of safe stage machinery operation lies the principle of direct operator control. When a human operator is tasked with initiating and guiding the movement of potentially heavy and complex equipment, they must possess the ability to instantly halt that movement should a hazard arise or if the situation demands it. This is where the concept of “preventing unintended movement” becomes crucial. Without a direct and continuous link between the operator’s active engagement and the machinery’s operation, the risk of accidents, damage, and injury significantly increases.

Operational Reliability vs. Safety Reliability

It’s important to differentiate between the general operational reliability of machinery and its reliability specifically concerning safety functions. Operational reliability refers to the machinery’s ability to consistently perform its intended production or artistic function over time without failure, impacting efficiency and potential downtime. Productions are often keenly focused on this aspect to ensure seamless shows. However, safety reliability, on the other hand, focuses specifically on the ability of safety-related components and systems (like the deadman handle and E-STOP) to function correctly and on demand to prevent hazardous situations.

While operational reliability aims for uninterrupted performance, safety reliability might, at times, introduce seemingly inconvenient stops or prevent machinery operation if unsafe conditions are detected. This can be perceived as an annoyance or a potential showstopper. However, the fundamental purpose of safety reliability is to prevent human injury or even fatalities. Ultimately, from both a human and a long-term economic perspective, a temporary halt to a performance due to a safety activation is far less costly and ethically preferable than dealing with the consequences of an accident. Ensuring robust safety reliability, even if it occasionally interrupts the flow, is a non-negotiable priority that safeguards human lives and mitigates potentially catastrophic outcomes.

The Role of the Deadman Handle Device

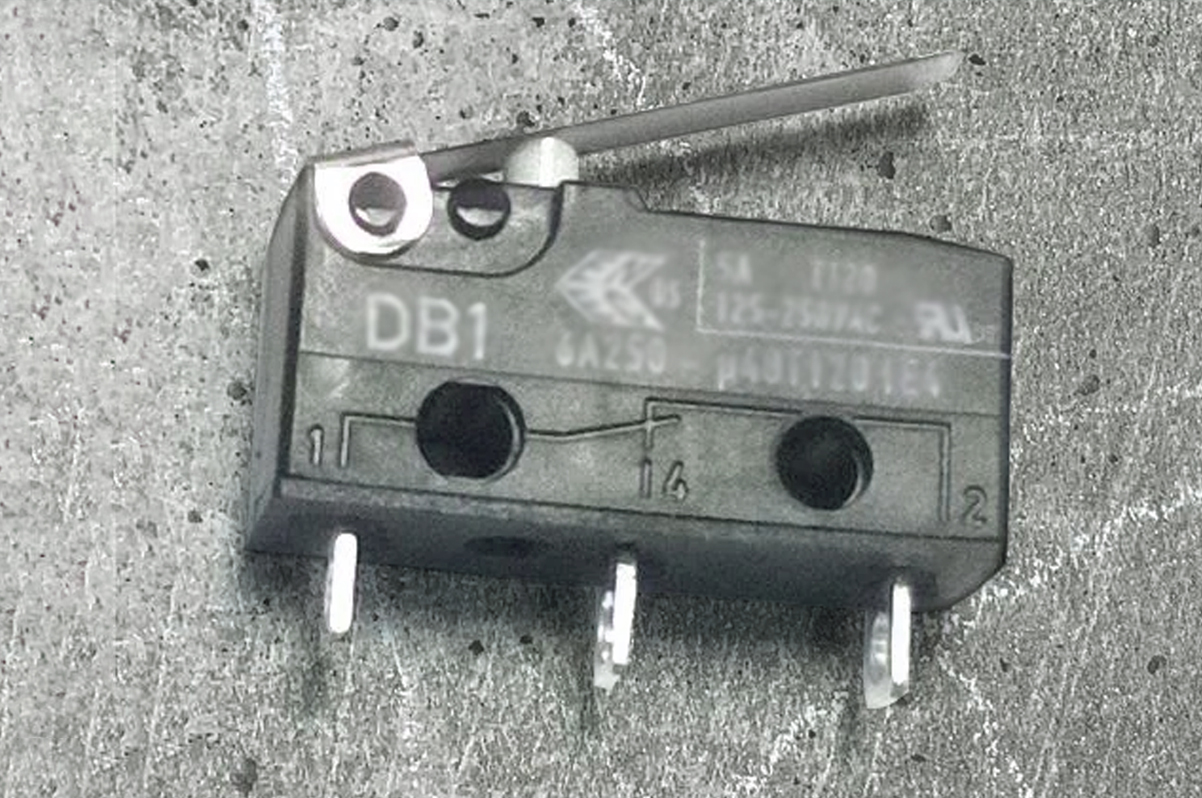

A deadman handle device directly addresses this fundamental safety requirement. In its essence, a deadman handle is a control that requires the operator to maintain physical contact – typically through continuous pressure – for the machinery to operate. If the operator releases the handle, the power to the machinery is immediately cut, and it comes to a stop. This inherent design ensures that movement is only possible when the operator is consciously and actively in control.

Applications Where Deadman Handles are Critical

Deadman handles are indispensable in applications where continuous operator control is necessary for safe operation. If machinery can be operated safely without a dedicated, continuously present operator – for example, with simple start and stop buttons – then a deadman handle device might not be required.

Certain machinery designs reduce risks through mechanical solutions, making their travel and operation fundamentally safe without a deadman handle. However, if a risk assessment conducted according to standards like EN ISO 13849 or EN IEC 62061 identifies the need for a deadman handle, then it must have an appropriate Safety Integrity Level (SIL) or Performance Level (PL) rating.

If the risk assessment outcome for a specific control function is “OM” (Organisational Measure), it implies that the risk can be adequately mitigated through procedures and training, and a dedicated safety-rated control like a deadman handle might not be mandatory. Conversely, if the assessment yields a result other than “OM,” the control function becomes a safety function requiring a defined SIL or PL.

Furthermore, if a risk assessment determines that spotters are needed to intervene and stop machinery, and the outcome is not “OM,” then a physical deadman device is generally required for the spotter. Radio or verbal communication between the spotter an the operator is insufficient. However, some codes of practice may allow the use of live CCTV monitoring by the operator as a means to enhance awareness and potentially avoid the need of spotters and therefore the need for additional deadman devices for them.

Safety Integrity Levels (SIL) and the Deadman Handle:

When a risk assessment determines that a deadman handle is a necessary safety measure for specific stage machinery, it’s crucial to understand that the device itself must be appropriately safety-rated. This rating is expressed as a Safety Integrity Level (SIL), which quantifies the level of risk reduction provided by a safety function. The higher the SIL (ranging from 1 to 4, with 4 being the most stringent), the lower the probability of dangerous failure. Note that SIL 4 is not an applicable level to machinery.

For stage machinery, the required SIL for a deadman handle is not always the highest level (SIL 3). The appropriate SIL is determined by a thorough analysis of the potential hazards associated with the machinery’s movement, the severity of potential injuries or damage, and the frequency of exposure to these hazards. In some cases, where the risks are lower or the exposure is less frequent, a deadman handle with a SIL 1 or SIL 2 rating might be deemed adequate to achieve an acceptable level of safety.

A manufacturer may be unable to claim on its own a SIL 3 safety function, EN 61508 requires at least a third-party document for the reliability of the safety devices used within the machinery.

The Impact of Power-Down Procedures on SIL Requirements

An important strategy in managing the required SIL for a deadman handle lies in the implementation of robust power-down procedures. When stage machinery is not in active use for rehearsals, performances, or maintenance, establishing a clear protocol to completely de-energize the equipment significantly enhances safety.

By cutting off the power supply, we effectively eliminate the energy source that could lead to unintended movement. In this secured, unpowered state, the immediate and continuous need for an actively engaged deadman handle is negated. The machinery is inherently safe against accidental operation.

This practice directly impacts the risk assessment process. By reducing the frequency of exposure to the hazard of moving machinery (because it’s powered down when not needed), the overall risk level can be lowered. Consequently, when the machinery is powered on and operational, the required SIL for the deadman handle might be reduced. For instance, a scenario that might initially necessitate a SIL 3 deadman handle could potentially be managed with a SIL 1 or SIL 2. In a scenario where the deadman handle required was SIL2 could potentially be managed without a deadman handle device if rigorous power-down procedures are consistently followed.

However, it is crucial to emphasize that this reduction in SIL requirement is contingent on the strict adherence to these power-down protocols. The risk assessment must consider the reliability and enforceability of these procedures. Furthermore, even with power-down procedures in place, the deadman handle must still be appropriately rated for the operational periods when the machinery is energized.

The Complementary Roles of Deadman Handles and Emergency Stops

It is crucial to understand the distinct yet complementary roles of deadman handles and Emergency Stop (E-STOP) devices in ensuring stage machinery safety.

A deadman handle serves as a proactive safety measure during normal operation. It ensures that movement only occurs with active operator engagement, providing continuous control and the ability to stop movement instantly by releasing the handle.

An Emergency Stop (E-STOP), on the other hand, is a reactive safety measure designed to halt machinery movement rapidly in the event of an unforeseen hazard or emergency. It acts as a fail-safe for situations where immediate cessation of all motion is required.

The Emergency Stop (E-STOP) cannot be used to prevent hazards that you can foresee. Therefore, if the machine is inherently unsafe and requires an operator to ensure its correct functioning, then the E-STOP is not enough.

Relying solely on an E-STOP for routine stops is not only improper but also potentially unsafe. E-STOP systems are designed for emergency use only. Furthermore, frequent use of an E-STOP can lead to unnecessary wear and tear on the system.

Both deadman handles and E-STOPs are vital components of a comprehensive safety system for stage machinery, but they serve different and equally important functions.

When a Deadman Handle might not be necessary?

While crucial in many applications, there might be instances where a traditional deadman handle is not strictly necessary or where alternative safety measures are more appropriate. This could include:

-

- Inherently safe machinery: For machinery that moves at extremely low speeds, with all the risk reduced with mechanical reduction methods, and that poses minimal risk of immediate harm.

- Machinery with Sophisticated Interlocking Systems: Some advanced systems incorporate complex interlocking mechanisms that prevent movement under unsafe conditions, potentially reducing the need for a continuous manual hold.

- Automated Systems with Robust Safety Protocols: Fully automated systems with rigorously tested and validated safety protocols might rely on sensors, light curtains, or other non-contact safety devices instead of a physical deadman handle. However, even in these cases, manual override controls with deadman functionality are often included as a backup.

Conclusion

The principle that an operator controlling moving machinery must have the means to prevent movement on demand is fundamental to achieving this. The deadman handle device stands as a critical tool in fulfilling this requirement in numerous applications, providing a direct and immediate link between operator engagement and machinery operation. Understanding the appropriate Safety Integrity Level for these devices and the role of robust power-down procedures further enhances the safety framework. While emergency stops serve as a vital complementary safety measure for unforeseen events, the proactive control offered by a properly specified and utilized deadman handle remains essential for safe and controlled operation during the dynamic performances that captivate audiences worldwide.