Upgrade or Substantial Modification?

Four years ago, we wrote an article concerning stage machinery modifications, specifically when a modified machine is considered new machinery.

At the time, the European Machinery WG MACHEX– a subcommittee of the European Senior Labour Inspectors Committee – was exploring the extent to which conditions may constitute grounds for a machine to require CE marking after a modification, in anticipation of the New Machinery Regulation.

Since then, the new Machinery Regulation (Regulation (EU) 2023/1230) was published on June 29th, 2023, and it will enter into force in January 2027. The Machinery Regulation introduces significant changes, including the definition of substantial modification.

The notion of ‘major modification’ targets modifications made by the final user that generate a change in the significant hazards associated with the modified machine.

Blumano is publishing a series of articles to explore the implications related to stage machinery upgrades or refurbishments. This series will provide readers with a clear understanding of what these modifications entail.

Considerations for Load Securing Devices

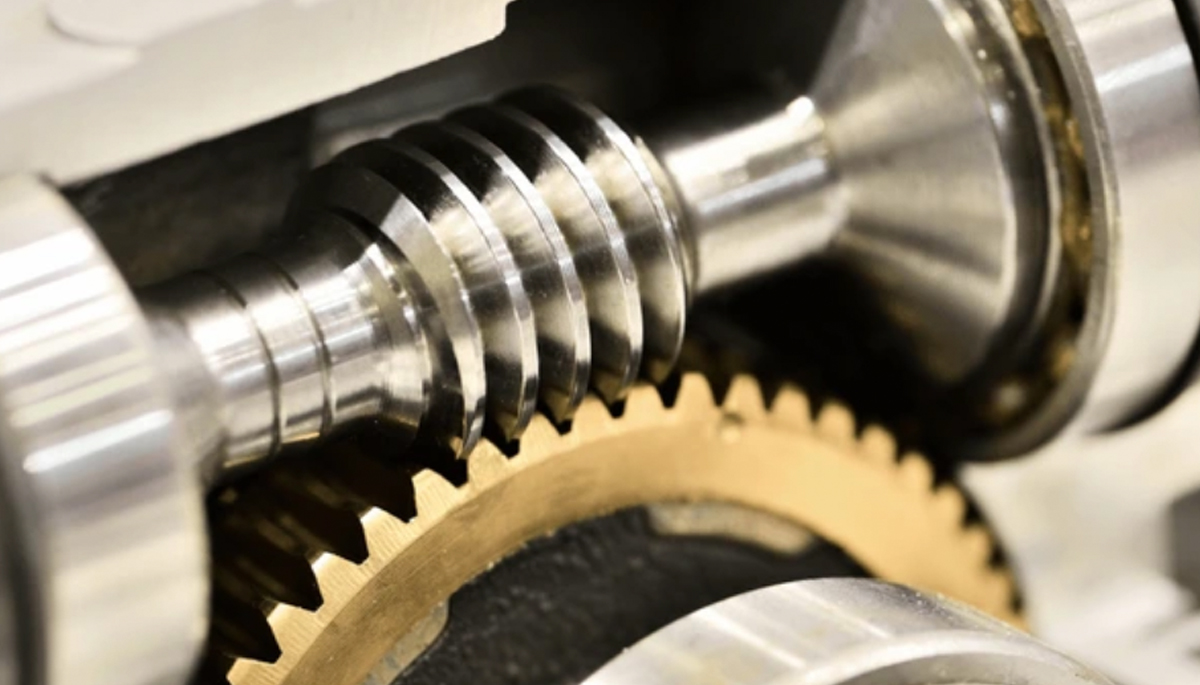

When upgrading the control system of stage machinery, such as theatrical fly bars or stage elevators, contractors may need to replace certain components for various reasons. These reasons could include incompatibility with the new control system, component obsolescence, or the need for features offered by the new system.

However, for load-securing devices like electromechanical brakes, a crucial aspect of such upgrades is the applied braking torque.

Braking Torque: A Critical Factor

Braking torque is the static torque required to prevent the brake from slipping. It represents the moment of braking force at the center of rotation.

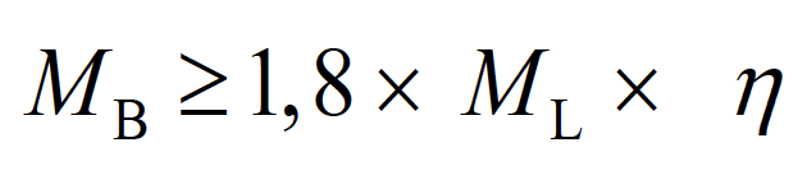

Brakes used for hoisting movements should meet the following formula:

Here, MB represents the specified holding torque of the brake at its shaft (speed ≤ 100 rpm), ML denotes the torque on the brake due to the rated load in a static condition (excluding mechanical efficiency), and η signifies the total mechanical efficiency of the load-carrying mechanism (including gear transmissions and load suspension).

Braking Torque vs. Braking Force

It’s important to distinguish braking torque from braking force, which is the tangential friction force between the brake pads and the disc.

The braking torque needs to be adequate for the allowed input torque, which is the minimum twisting force applicable to the gearbox’s input shaft without causing damage.

This maximum input torque depends on several factors, including gearbox design, material, and manufacturing quality.

The Importance of Technical Data

Therefore, when upgrading stage machinery without access to technical documentation (calculations, fatigue reports, data sheets, etc.), replacing a brake with a different one having non-matching specifications can pose a safety risk.

The Machinery Regulation considers such modifications, where a new risk is introduced or cannot be mitigated with existing measures (e.g., replacing a brake with a different one), as substantial modifications.

Furthermore, EN 17206, section 9.4.1, considers the “modification of drives and brakes” a substantial change. However, it clarifies that replacing parts with identical specifications is not considered a substantial change.

Conclusion

When replacing original brakes with a different design during stage machinery refurbishment and lacking technical information about the machinery’s structural and mechanical parts, the contractor must demonstrate that the upgrade introduces no new risks.

Failure to do so constitutes a substantial modification, requiring re-issuance of the CE marking for the machinery.