MACHINERY RISK ASSESSMENTS

Complementary Services

Within Machinery Risk Assessment, we offer a variety of complementary services such as:

What is a machinery risk assessment and why do you need it?

If you’re a manufacturer of stage machinery or control systems or a system integrator or end user, then during your product’s life cycle a stage machinery risk assessment will be required by law and must follow Machinery Directive 2006/42/EC or EN 17206:2020. Not only is a risk assessment required, but it’s also the core of the machinery’s technical file.

A risk assessment is composed of a risk analysis where you identify the stage machinery’s related hazards, their potential consequences and the initial risk estimation. To reduce any risks noted in the risk analysis, you must carry out the risk reduction process in order to establish the protective measures needed to decrease the risks.

At BLUMANO, we use the principals and methodology of EN ISO 12100:2010 to conduct risk assessments and risk reductions. Our extensive experience in the entertainment industry makes us specialists in assessing machinery, machinery assemblies, flying performer installations, scenic movements and lifting operations. Additionally, we will consider all applicable variables such as access to the machinery, adverse weather affects or unintentional movements.

We’ve also developed exclusive tools to efficiently deliver complete, clear and concise risk assessments.

Since the entertainment industry is always changing and adapting, conducting a thorough risk assessment is a crucial step in providing a safe work environment for performers, technicians and the audience.

Click on the button below for more information on BLUMANO’s exclusive risk assessment tools and training. Our products will give you and your organisation an in-depth understanding of the fundamental steps of the process and will teach you how to carry out a risk assessment.

Curious? See what we can do for you. Click here to explore StageDB.

What we offer

BLUMANO will help you determine what deliverables may be necessary within the scope of this service.

Risk Analysis – EN 12100

Risk Assessment – Validation – EN 12100

Risk Assessment – Compilation – EN 12100

3rd Party Risk Assessment Evaluation

Handover Reports

Gap Analysis – Related to the Machinery Directive

Safeguarding and Complementary Measures – EN 12100 Safety Recommendations

EHSR – Machinery Directive 2006/42/EC

Compliance – European – EN 17206

Method Statements

Safe Installation and Commissioning Guidelines

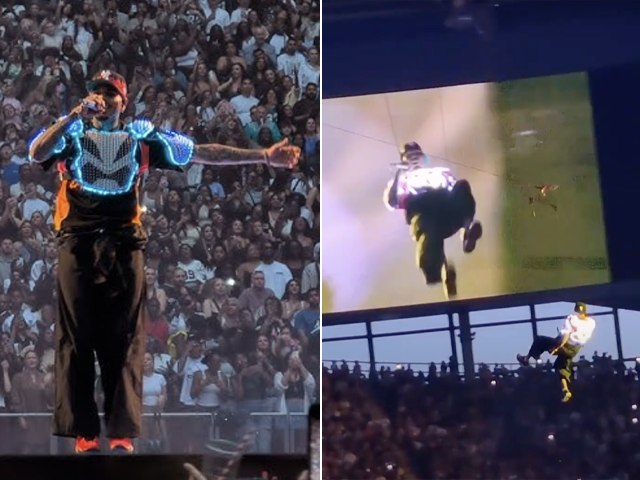

Chris Brown | Breezy Bowl XX

Chris Brown | Breezy Bowl XX Simply Red | 40th Anniversary Tour

Simply Red | 40th Anniversary Tour Robbie Williams | Britpop Tour

Robbie Williams | Britpop Tour