When estimating the probability of occurrence of a risk, one of the elements that needs to be considered among others is the frequency and duration of exposure to the hazard; this factor has a big influence in the output of the risk estimation and it needs to be carefully assessed.

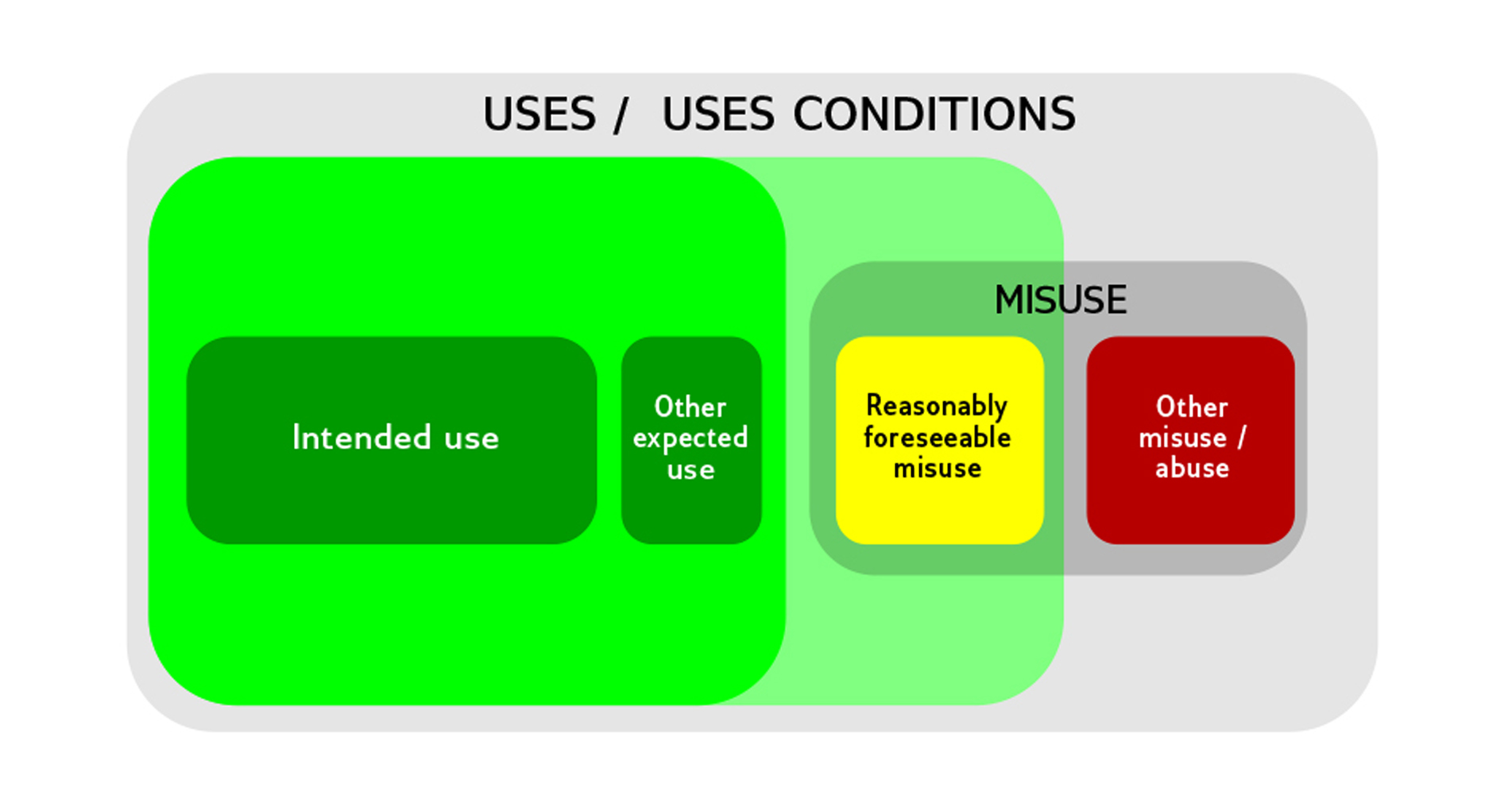

Every stage machinery should be designed to take into consideration time, space and use limits, where the “use limits” are the main factors foreseen concerning the exposure of a person to the hazards associated with the machinery. Some examples of such factors to be analysed are the need for access to the hazard zone, the nature of it, the time spent, the frequency of access, etc. However, at some point of the risk analysis process, the initial risks need to be estimated and the frequency of exposure element score must be determined. There is a big dilemma of when the low frequency of exposure can be claimed and when instead the frequent and continuous exposure needs to be considered.

As a general guideline, we can become inspired with the approach used in two functional safety standards and analyse if they are suitable to be applied to a global machinery risk assessment estimation.

.

Long exposure to a risk: F2

High and low, long and short, 1 and 2: probably the simplest way to define the frequency element-of-risk levels is to divide them into at least two categories.

F1 (where F represents the Frequency of Exposure) is used in a functional safety standard1 to define a seldom-to-less-often exposure, with a short time duration of exposure (low exposure, short exposure).

Consequently, in the same standard F2 is used to define a frequent-to-continuous exposure, with a long-time duration of exposure (high exposure, long exposure).

So apparently, the evaluation of the frequency of exposure could be as simple as: long or short, F1 or F2.

We bet that the first thought you may have now is How long is “long” and how short is “short”?

Figure 1 – Exposure.

Unfortunately, a clear boundary for the selection between F1 and F2 cannot be stated. The standard contains the non-prescriptive instruction that in cases where the person’s risk exposure occurs more frequently than once per hour or if the interval of exposure is once every 15 minutes, F2 should be always selected. And this instruction is generally appropriate for all cases occurring in practice, in any industry and related to any machinery. Hence, during the evaluation, an average value should be assigned for the hazard exposure which is commensurate with the overall time for which a machinery is in use. But… when can F1 be claimed?

.

Short exposure to a risk: F1

So F2 should be selected if a person is frequently or continuously exposed to a hazard; it would be irrelevant whether the same or different persons are exposed to the hazard on successive exposures, e.g. different members of an acting company using a lift or standing under moving scenery. The frequency parameter should be chosen according to the frequency and duration of exposure of all persons to the hazard.

According to ISO 13849-1:2015, it is possible to assign F1 if the accumulated exposure time is not exceeding the 1/20 of the global functioning time of the machinery and if the frequency of exposure doesn’t exceed one every 15 minutes. The accumulated exposure time should consider assembly, rehearsals and showtime, and deal with the foreseeable human behaviour especially during commissioning and setting time.

The global functioning time parameter can be tricky to determine, since it can vary depending on the hazard. Therefore, the global functioning time of a machinery related to the hazard of an “unintentional start-up / stop” may be related to the entire period of time in which the machinery drive is connected to the power supply, where “exceeding a specified speed” global functioning time may be only related to the actual time the machinery is in motion. Again, each evaluation has to consider the appropriate context.

.

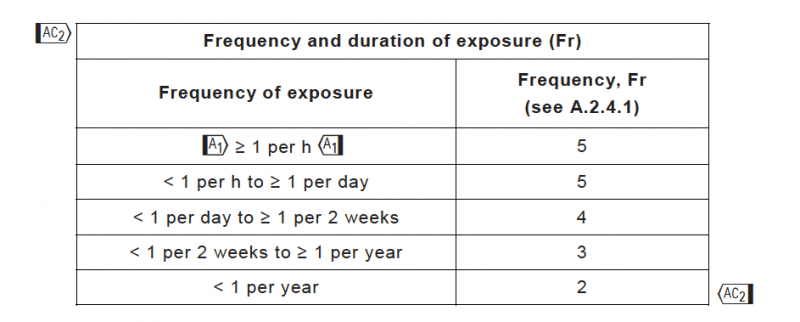

Other exposure classifications: Fr

According to another functional safety standard2, it should be possible to estimate the average interval between exposures – therefore the average frequency of access – and for it to be possible to foresee the duration, for example, if the duration will be longer than 10 minutes. Hence, that 10 minutes seems to be a reference value of the duration of exposure that will be considered.

Table A – Frequency and duration of exposure (Fr) classification.

The standard3 gives a frequency and duration of exposure classification table in which the frequency of exposure Fr is divided in five element-of-risk levels:

| ≥ 1 per h | Score 5 |

| < 1 per h to 1 per day | Score 5 |

| < 1 per day to 1 per 2 weeks | Score 4 |

| < 1 per 2 weeks to 1 per year | Score 3 |

| < 1 per year | Score 2 |

.

It also says that if the duration of the exposure is shorter than 10 minutes, the value may be decreased to the number in the row below, but this does not apply to the frequency of exposure of 1 h, which should not be decreased at any time. Don’t forget that the time of exposure is related to a specific hazard a person interacting with a particular machinery in the hazard zone can be exposed to; do not confuse the time of exposure to a hazard with the time of exposure related to a specific application (this is important for machinery integrated in temporary installations which may expose people to identical hazards during different installations).

.

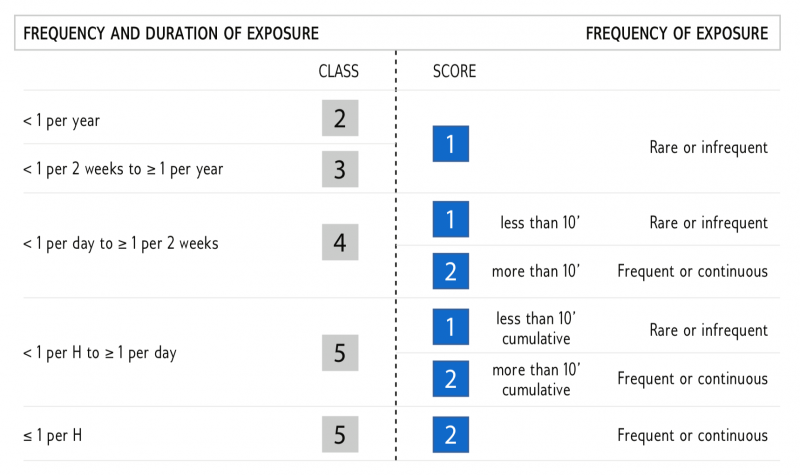

Can F and Fr be compared?

The approach that these two standards have towards the estimation criteria of the frequency of exposure are very different and they may not be directly comparable, but it is possible to draft a reference table as a general guideline.

NOTE:

Rare of infrequent

< 1 per year or < 1 per 2 weeks to 1 per year, interval of exposure is so long that the 1/20 of the global functioning time can be easily achieved and bring the estimation to F1.

Frequent or continuous

We understand that the ≥ 1 per h parameter cannot be reduced, and although in some circumstances F1 can be achieved even if there is more than one exposure per hour, we chose to stick to F2 as a general rule.

Middle Ground

The < 1 per day to 1 per 2 weeks and < 1 per h to 1 per day are the most common scenarios in the entertainment industry for a stage machinery’s frequency of exposure. There are many ways to allocate F1 or F2 to the parameters above and one of these ways is to apply the 10 minute threshold adding the element of cumulative vs non-cumulative.

Table B – Frequency and duration of exposure: F vs Fr.

Table B – Frequency and duration of exposure: F vs Fr.

.

Conclusion

We believe that a clear demarcation from what is low exposure and what is long cannot be carved in stone, however, it is important to have some reference parameters to follow and – sometimes – to challenge it. If we try to define lengths, duration and establish a criterion, if we work with it and we analyse the output, maybe we still will not be able to answer the question of How long is a piece of string? …but we are getting very, very close.

.

.

1. ISO 13849-1:2015

2. EN 62061:2005+A2:2015

3. EN 62061:2005+A2:2015